Solid Mechanics and Metal Forming Laboratory

Primary Researcher(s) / Coordinator(s): Assist. Prof. Dr. Mert Efe

General Information

Equipments

Completed and Ongoing Research Projects

General Information

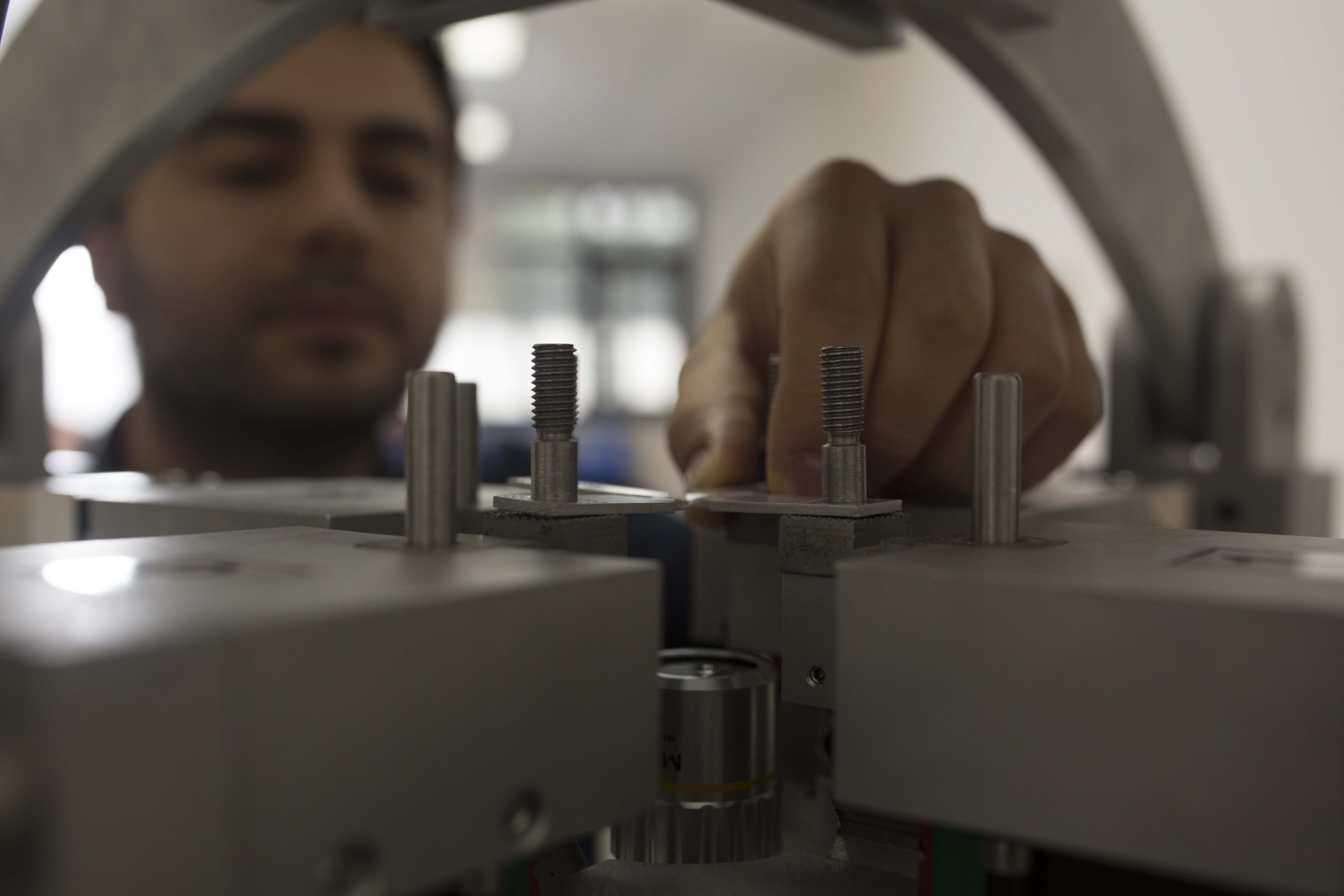

Our aim is to observe the in-situ formation and evolution of the surface defects during metal sheet forming by means of a novel test mechanism involving high-resolution photography and digital image correlation (DIC) techniques. As an alternative to conventional macro-scale tests, we investigate the mechanical behavior of materials at microstructure scale (grain-scale). Interactions between microstructure evolution and defect formation will be analyzed, which results in solutions for will defect minimization and elimination during metal forming.

Equipments

- Shimadzu Bending Test Machine capasity of 10 kN

- Navitar Zoom 6000 Lens Setup

- Sunline 852D+ SMD Rework Station

- Herkules Air Compressor

- Basler Pilot piA2400-17gc CCD camera

- Navitar Led Controller Light Source

- Badsector Air Compressor

- Badsector Airbrushes

- Erikson Cupping Machine

Completed and Ongoing Research Projects

- M. Efe (PI), “In-Situ Observation and Control of Microstructure and Surface Defect Evolution during Magnesium Sheet Forming,” 2014-2018, Marie Curie Career Integration Grant, Funded by European Commission Research Executive Agency

- M. Efe (PI), “Formability of Dual-Phase Steels at High Temperatures and Industrially Relevant Deformation Rates”, 2015-2018, 3501 – National Young Researcher Career Development Program, Funded by: The Scientific and Technological Research Council of Turkey (TÜBİTAK)

- M. Efe (PI), “In-Situ Analysis of Magnesium Sheet Forming,” 2014-2016, Career Integration Fellowship, Funded by: The Scientific and Technological Research Council of Turkey (TÜBİTAK)

- Dr. Osman El-Atwani, Los Alamos National Laboratory, USA

- Dr. Caner Şimşir, Metal Forming Center of Excellence, Atılım University, Turkey

- Dr. Dinakar Sagapuram, Texas A&M University, USA

- Dr. Wilfredo Moscoso, Wichita State University, USA

Last Updated:

11/07/2019 - 17:54